Critical Asset Monitoring – Know before the glow!

The Logika Thermal Monitoring System leverages advanced thermal cameras with monitoring software to provide plant operators with a solution to keep equipment running and workers safe.

Industrial plants across the globe are more advanced and automated than ever – despite this, plant operators still require routine inspections of critical equipment to ensure that the hot stuff stays contained. EAF shells, ladles, kilns, boilers, and reheat furnaces – to name a few – all require skilled technicians to inspect the layers of refractory insulation for wear and to recommend repairs and relining. This is a time-consuming endeavor that can put workers at risk.

With Logika TMS, plant operators can employ real-time monitoring of critical assets and can alert workers of potential risk long before an expensive and potentially dangerous failure. Logika TMS allows plant operators deep insight into the thermal activity of not only the above-mentioned refractory-lined vessels, but also motors, bearings, switchgear and other assets critical in a plant’s safe and reliable operation.

If you want to identify hot spots in ladles or cold spots in an EAF indicative of a water leak, the Logika TMS is the right solution for you.

While safety is the primary driver of the Logika TMS, plant engineers have found that the system also allows for reduced physical inspections and optimized maintenance schedules.

Let’s take a look at how the system works:

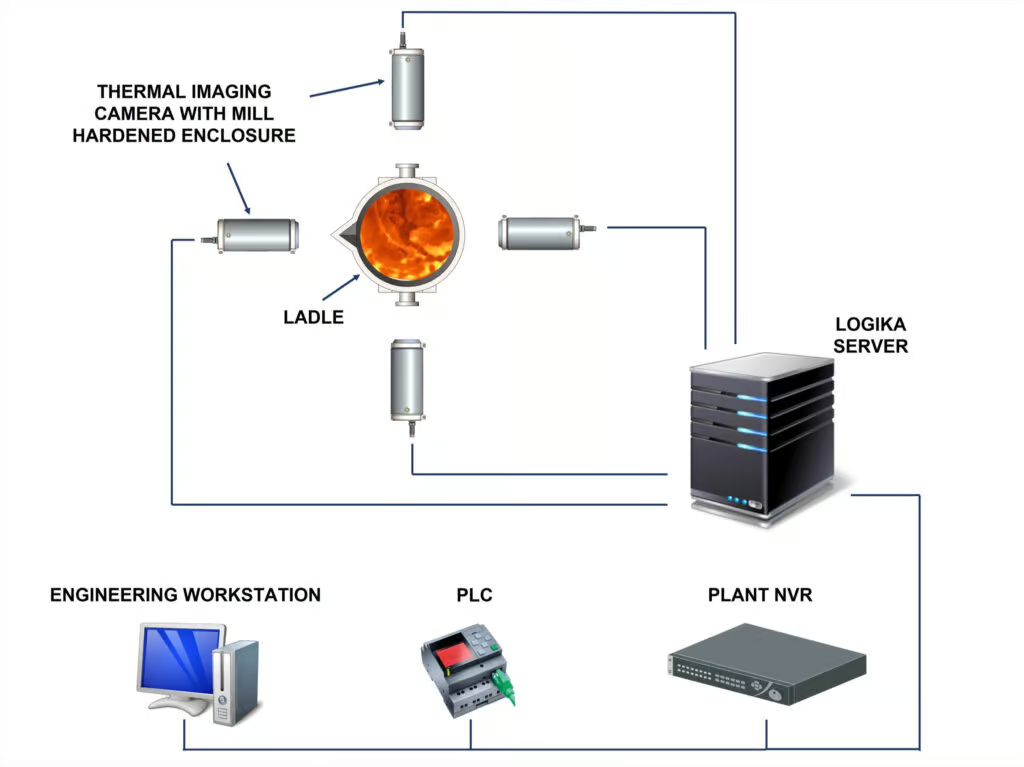

System Overview

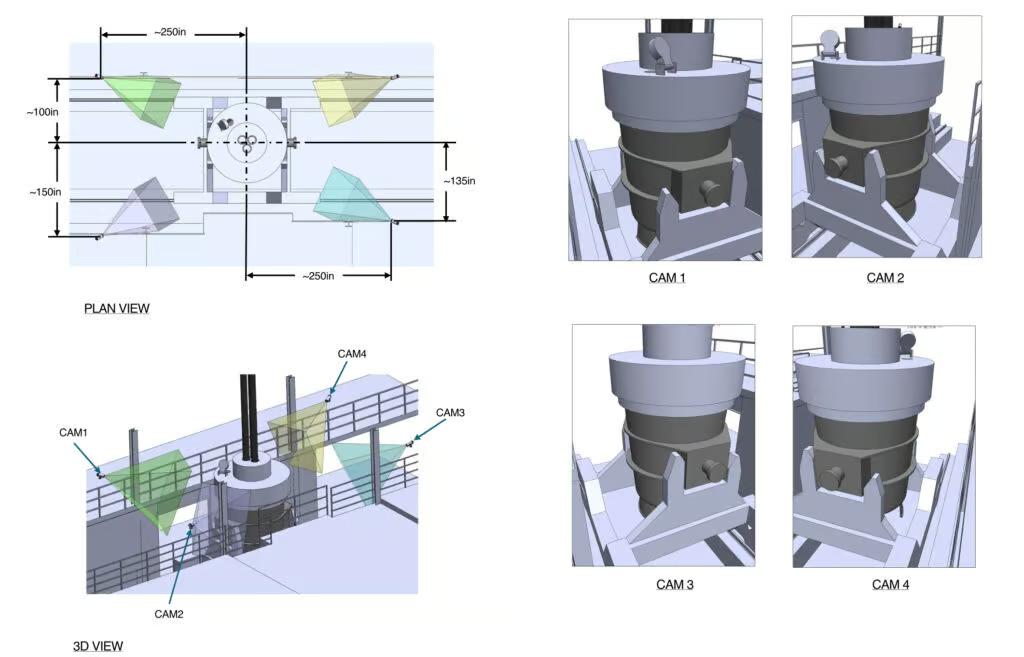

Like all of Logika’s advanced machine vision solutions, the software is the heart of the system. TMS software can interface with up to six thermal cameras to provide adequate asset coverage. Through the HMI, users can define regions-of-interest and alarm thresholds. Out of the box, a lower-level warning and higher-level alarm threshold can be set – each will send separate signals to plant PLCs. Warning and alarm thresholds can be based on either temperature or temperature rate-of-change.

While the HMI provides operators with a real-time view of their critical assets, the TMS software is constantly logging temperature data for analysis by plant engineers who may be focusing on a preventative maintenance schedule or RCA, for example.

The software can only function if the hardware it speaks to is robust and reliable. To that end, our thermal cameras come housed in the same mill-hardened casings used in visual-spectrum applications. These casings can be either liquid or air cooled with the use of a Vortex cooler.

Logika TMS ship ready to go with ModbusTCP protocol. Different protocols can be optioned to work with your mill’s specific PLCs.

Let’s get started!

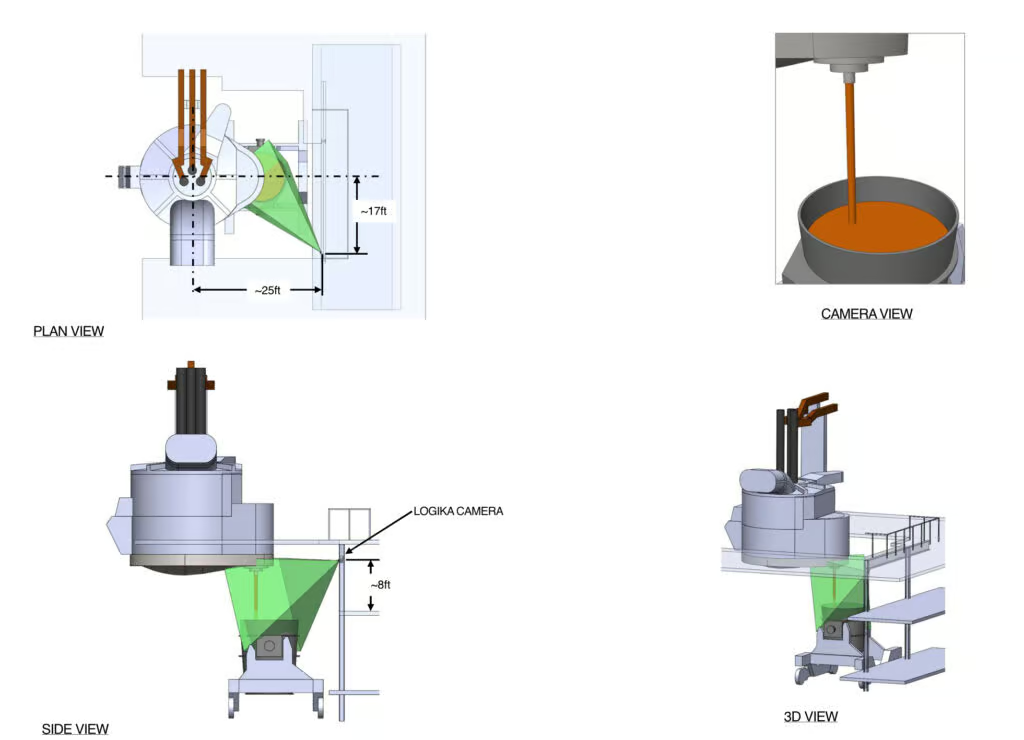

Inquire today about Logika TMS. We’ll start with a virtual meeting to understand the specifics of your mill, then follow up with an onsite evaluation. From there, the real work begins on our end. Logika engineers will design the perfect integration for your TMS. Deliverables will include 3D field-of-view studies by Logika engineers to ensure that your assets are covered. Logika engineers can be made available for commissioning as well.

Inquire today about the Logika Thermal Monitoring System.